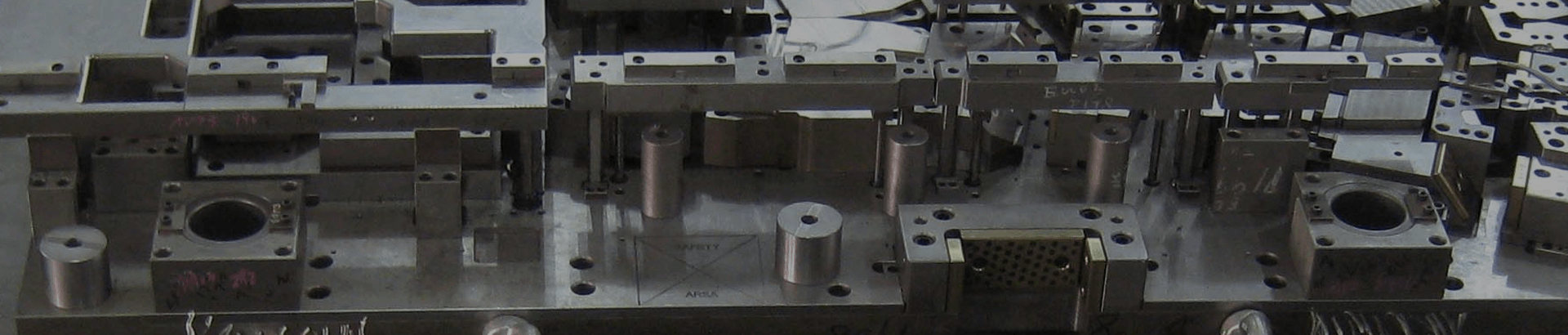

Injection molding is an essential process in manufacturing, widely used to create complex parts with multiple materials. Two of the most popular techniques for multi-material components are overmolding and two-shot injection molding. Although these processes seem similar, they are distinct methods with unique applications and benefits. Understanding the differences between overmolding and two shot injection molding can help businesses choose the right technique based on their design and production needs.

Process Complexity: Overmolding is simpler and can often be done using standard injection molding machines. Two shot injection mold, however, requires specialized machines with rotating or shifting molds, making it more complex and costly initially.

Bonding Strength: Two-shot molding typically offers stronger bonding between materials, as both are injected in quick succession within the same cycle. In overmolding, the materials bond well, but since the layers are applied in separate steps, the bond may not be as strong as in two-shot molding.

Production Speed: Two shot injection molding is more efficient in high-volume production because it completes the part in a single cycle. Overmolding, on the other hand, involves two separate injection cycles, increasing production time per part.

Cost: For lower-volume production or simpler parts, overmolding is generally more cost-effective since it requires less specialized equipment. Two shot injection molding, though more costly to set up, can be more economical in high volume runs due to its speed and efficiency.

Design Complexity: Two-shot molding is ideal for creating intricate designs with precise color separations and material combinations, as both materials are injected in one mold. Overmolding is better suited for simpler designs, but it offers more flexibility in the types of materials that can be layered together.

Overmolding and two shot injection molding are both valuable techniques in today’s manufacturing industry. Overmolding provides flexibility and is ideal for products that benefit from an additional layer for grip or comfort. Two shot injection molding, meanwhile, offers speed and durability, making it suitable for high volume production where intricate designs are required.

+1 270-282-2096

+1 270-282-2096