Creating a plastic mold is a critical step in the manufacturing process, especially for industries like automotive and toy production. Understanding the time required to create a custom plastic mold can help businesses plan their production schedules effectively.

The timeline for making a plastic mold can vary widely based on several factors, including the complexity of the design, the size of the mold, the type of materials used, and the manufacturing processes involved. On average, the entire process can take anywhere from a few weeks to several months.

Initial Design and Prototyping

The first stage in creating a plastic mold is the design phase. This is where engineers and designers collaborate to develop the mold specifications. For projects like a module plastic case for automobiles, precision is key. The design needs to accommodate various components while ensuring optimal fit and functionality. Depending on the complexity, this design phase can take from a few days to several weeks.

Once the design is finalized, a prototype is often created using rapid prototyping techniques. This allows for testing and modifications before the final mold is produced. Prototyping can add another week or more to the timeline, but it’s a crucial step to ensure that the mold will perform as expected.

Material Selection and Mold Fabrication

After the design is approved, the next step is selecting the appropriate materials for the mold itself. High-quality steel or aluminum is commonly used for molds due to their durability and ability to withstand high temperatures. The choice of material can impact both the cost and the production time.

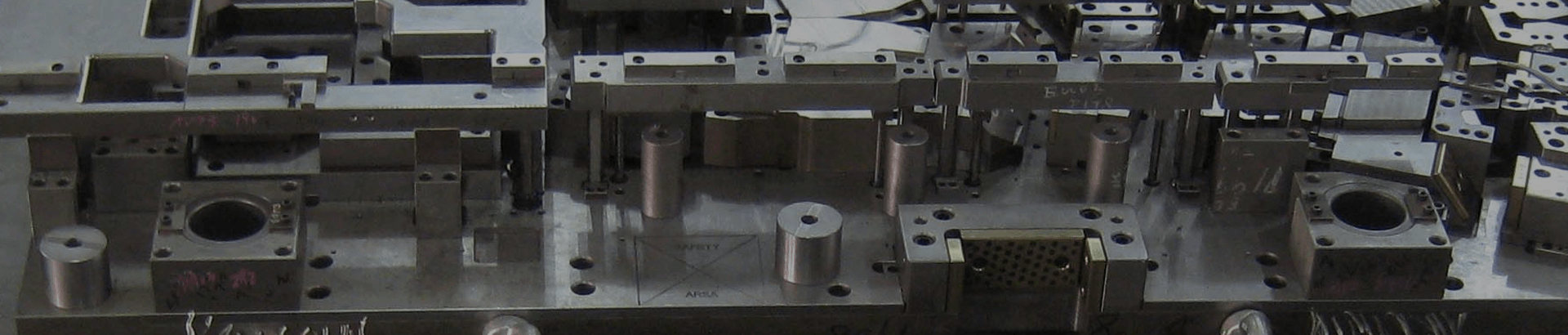

The actual fabrication of the mold involves various machining processes, including milling, EDM (Electrical Discharge Machining), and grinding. For a custom plastic injection molding project, these steps can be intricate and time-consuming. Typically, this phase can take anywhere from three to six weeks, depending on the mold's complexity and the manufacturer's capacity.

Testing and Adjustments

Once the mold is fabricated, it undergoes testing to ensure it produces the desired results. This step is crucial, especially for products like plastic smart toys injection molding, where safety and functionality are paramount. If any issues are identified during testing, adjustments may be necessary, which can further extend the timeline by several days or even weeks.

Final Production

Once the mold has passed all tests and any necessary adjustments have been made, it is ready for production. At this stage, the actual injection molding process can begin, allowing manufacturers to produce the plastic components required for their projects.

In summary, the timeline for creating a plastic mold is multifaceted and can vary greatly. From initial design to final production, the entire process may take anywhere from six weeks to several months. Understanding these timelines helps businesses make informed decisions, ensuring that their production schedules align with market demands.

For those looking to produce high-quality plastic components, partnering with experienced manufacturers in custom plastic injection molding is crucial. They not only streamline the mold-making process but also ensure that the final products meet industry standards and specifications. Whether it’s a module plastic case for automobiles or innovative plastic smart toys, the right approach can significantly impact production efficiency and overall success.

+1 270-282-2096

+1 270-282-2096