Plastic molding has been a go-to manufacturing process for producing a wide range of products, from everyday household items to industrial components. However, due to environmental concerns associated with plastic waste and pollution, industries and consumers alike are seeking sustainable alternatives. With growing awareness about the harmful impact of plastic on ecosystems, the search for more eco-friendly solutions is becoming increasingly important.

1. Biodegradable Materials

One promising alternative to plastic injection molding is the use of biodegradable materials. These materials are designed to decompose naturally in the environment, reducing long-term pollution. Bioplastics, made from renewable resources like cornstarch, sugarcane, and other plant-based materials, are leading this movement. Unlike traditional plastics derived from petroleum, bioplastics offer the advantage of being compostable under specific conditions, significantly reducing their environmental footprint. These materials can be molded into products just like traditional plastics but decompose much more rapidly when exposed to certain environmental factors, such as heat and moisture.

2. 3D Printing

3D printing, also known as additive manufacturing, is another alternative to traditional plastic molding. This technology allows for the creation of three-dimensional objects from digital models, typically layer by layer. One of the key benefits of 3D printing is its ability to minimize material waste. Traditional plastic molding processes often result in excess material, which can contribute to waste. In contrast, 3D printing uses only the material needed to create the product. Additionally, it offers more design flexibility and faster prototyping, which can make manufacturing more efficient.

3D printing can use a variety of materials, including metals, ceramics, and even biodegradable plastics, making it a versatile option for producing eco-friendly products.

3. Natural Fiber Composites

Another sustainable alternative to plastic molding is the use of natural fiber composites. These materials combine natural fibers like flax, hemp, or jute with a resin matrix to create durable, lightweight products. Natural fiber composites have gained popularity in industries such as automotive and construction, where their strength and environmental benefits are highly valued. These materials are not only renewable but also biodegradable, making them a more sustainable option compared to traditional plastic composites. They also offer the added benefit of reducing the overall carbon footprint of the product, as the production of natural fibers tends to be less energy-intensive than the extraction and processing of petroleum-based plastics.

Recycling is one of the most straightforward alternatives to reducing plastic waste. Instead of creating new plastic products from raw materials, recycled plastics can be molded into new products. This process not only reduces the need for virgin plastic production but also helps divert plastic waste from landfills and oceans. Companies are increasingly adopting recycled plastic molding processes, especially in industries like packaging, automotive, and consumer goods. In some cases, manufacturers are also blending recycled materials with other eco-friendly alternatives to enhance their sustainability.

5. Wood and Bamboo

Wood and bamboo offer a more traditional yet sustainable alternative to plastic molding. These natural materials are renewable, biodegradable, and have been used for centuries to create durable products. With advancements in technology, wood and bamboo can now be molded into various shapes and forms to replace plastic in certain applications. Bamboo, in particular, grows quickly and requires minimal resources to cultivate, making it a highly sustainable option. From kitchen utensils to furniture and even packaging, wood and bamboo are becoming more prevalent as alternatives to plastic-based products.

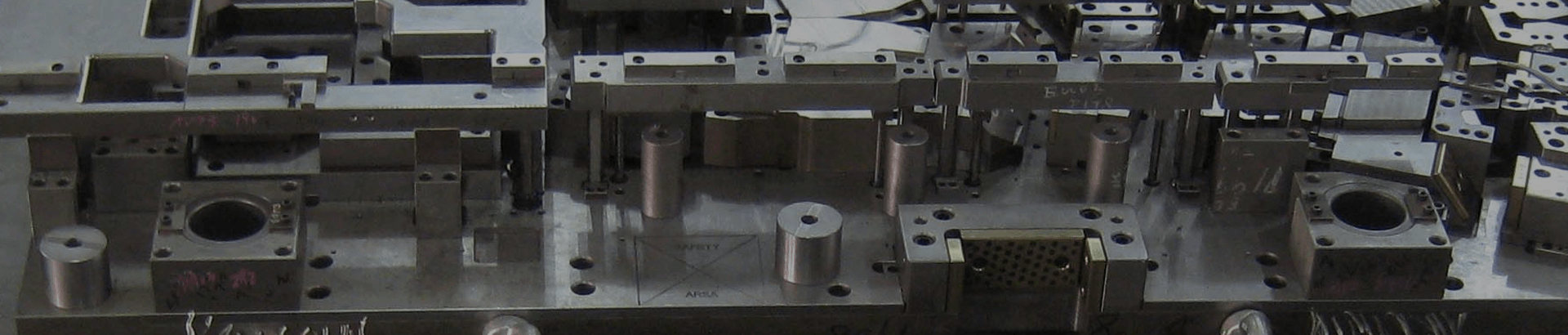

As the world becomes more conscious of the environmental impact of plastic, alternatives to plastic molding are gaining traction. Biodegradable materials, 3D printing, natural fiber composites, recycled materials, and renewable resources like wood and bamboo offer promising solutions to reduce plastic waste and promote sustainability. While Plastic injection molded parts is still widely used, these alternatives represent a step towards a greener, more sustainable future. By adopting these options, industries can significantly reduce their reliance on plastic and contribute to a healthier planet for future generations.

+1 270-282-2096

+1 270-282-2096