Plastic injection molding is a widely used manufacturing process for producing plastic parts by injecting molten plastic into a mold. This versatile technique can create complex shapes and sizes, making it the go-to method for many industries, including toys, automotive, electronics, and consumer goods. Whether you're creating small plastic components or large automotive parts, plastic injection molding offers precision and efficiency.

Applications of Plastic Injection Molding

One of the most popular applications of plastic injection molding is plastic toy molding. Toys require intricate designs and durability, and this process can efficiently produce high-quality toys that are safe for children. The ability to replicate fine details makes it an ideal method for creating everything from action figures to building blocks.

Another major use of this technology is in automotive plastic injection molding. Many components in vehicles, such as dashboards, bumpers, and interior panels, are produced using plastic injection molding. These parts are lightweight, durable, and cost-effective, helping automotive manufacturers meet safety and performance standards while maintaining affordability.

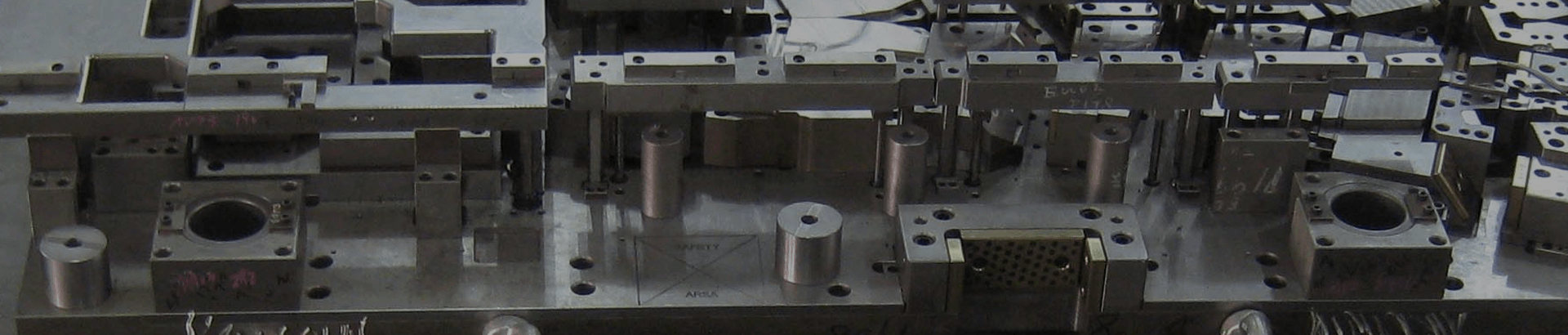

The Process Behind Plastic Injection Molded Parts

The plastic injection molding process begins with heating plastic pellets until they melt into a liquid state. This liquid is then injected into a custom-designed mold at high pressure. Once the plastic cools and hardens, it takes the shape of the mold. The finished products, known as plastic injection molded parts, are then ejected from the mold and inspected for quality. This process is repeated, allowing for high-volume production of identical parts.

With the right design and material selection, custom plastic injection molding can produce parts tailored to specific needs. Whether you need a prototype or a final product, customization ensures that the plastic components meet precise specifications in terms of shape, color, and functionality.

Why Choose Kenmold for Plastic Injection Molding?

Kenmold is a leader in the field of plastic injection molding, offering a range of services that cater to different industries. Our expertise includes plastic toy molding, automotive plastic injection molding, and creating high-quality plastic injection molded parts for various applications. Kenmold is different in that we can provide customized plastic injection molding solutions to meet the unique needs of our customers.

At Kenmold, advanced technology, a dedicated team, and stringent quality control ensure the best results. Whether you're in the toy industry or the automotive sector, Kenmold’s plastic injection molding services are designed to deliver efficiency, precision, and cost-effectiveness.

+1 270-282-2096

+1 270-282-2096