In automotive manufacturing, the use of automotive molds is crucial. These molds are meticulously designed to create specific components that fit seamlessly within vehicles. The molding process ensures that the resulting parts are lightweight yet durable, making them ideal for a wide range of automotive applications—from interior panels to exterior body components. The precision of automotive mold makers allows for the efficient production of complex shapes, which enhances both functionality and aesthetics.

Automotive plastic injection molding is a widely used technique that streamlines production while maintaining high-quality standards. During this process, heated plastic is injected into molds under high pressure, allowing it to take on the desired shape. This method not only reduces waste but also enables manufacturers to produce large quantities of parts quickly and efficiently. As a result, automotive companies can respond to market demands without compromising on quality.

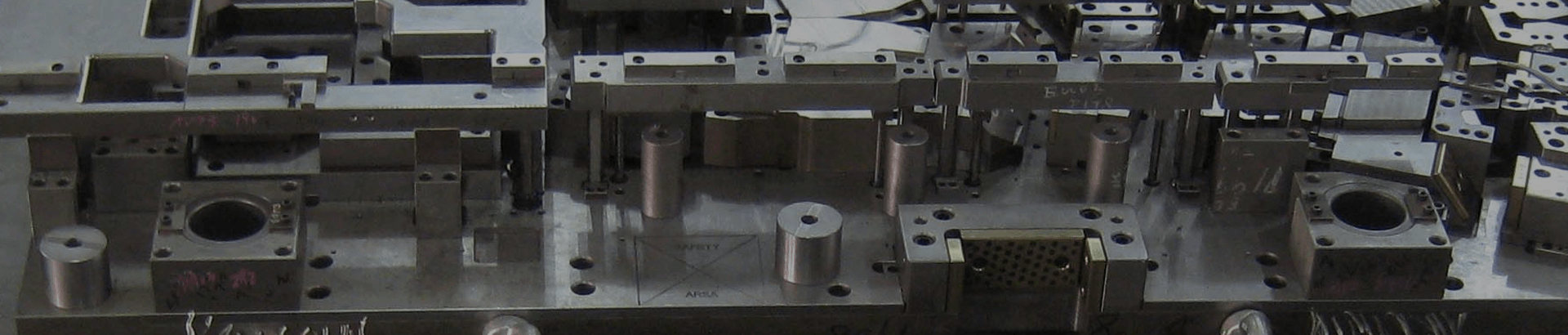

When it comes to choosing a partner for automotive plastic injection molding, Kenmold stands out in the industry. With years of expertise and a commitment to quality, Kenmold excels in creating custom molds tailored to specific automotive needs. Their state-of-the-art facilities and experienced team ensure that every product meets stringent industry standards. Moreover, Kenmold's focus on sustainable practices makes them a responsible choice for manufacturers looking to minimize their environmental impact.

In summary, the process of making plastic for cars is integral to the automotive industry, leveraging advanced techniques like automotive molds and plastic injection molding. Companies like Kenmold not only provide high-quality solutions but also demonstrate a commitment to innovation and sustainability in automotive manufacturing.

+1 270-282-2096

+1 270-282-2096