China injection molding is a highly versatile manufacturing process widely used in the automotive industry to produce a variety of parts. Some common automotive parts made by injection molding include:

1.Interior Components:

Dashboard panels

Glove compartments

Center consoles

Door panels

Air vent grilles

Instrument panels

Steering wheel components

2.Exterior Components:

Bumpers

Grilles

Mirror housings

Headlight and taillight covers

Fender flares

Spoilers

Door handles

3.Engine Components:

Engine covers

Air intake manifolds

Battery covers

Radiator end tanks

4.Electrical and Electronic Components:

Connector housings

Fuse boxes

Light housings

Sensor housings

5.Functional Components:

Clips and fasteners

Cable ties

Grommets

Seals and gaskets

6.Under-the-Hood Components:

Reservoirs (coolant, windshield washer fluid, etc.)

Fan shrouds

Air ducts

7.Seating Components:

Seat bases and backs

Armrests

Headrests

Seatbelt components

Automotive plastic injection molding is preferred for these parts because it allows for high precision, consistency, and the ability to produce complex shapes. It is also efficient for mass production, offering economies of scale and material versatility, as various thermoplastic and thermosetting polymers can be used to meet different performance requirements.

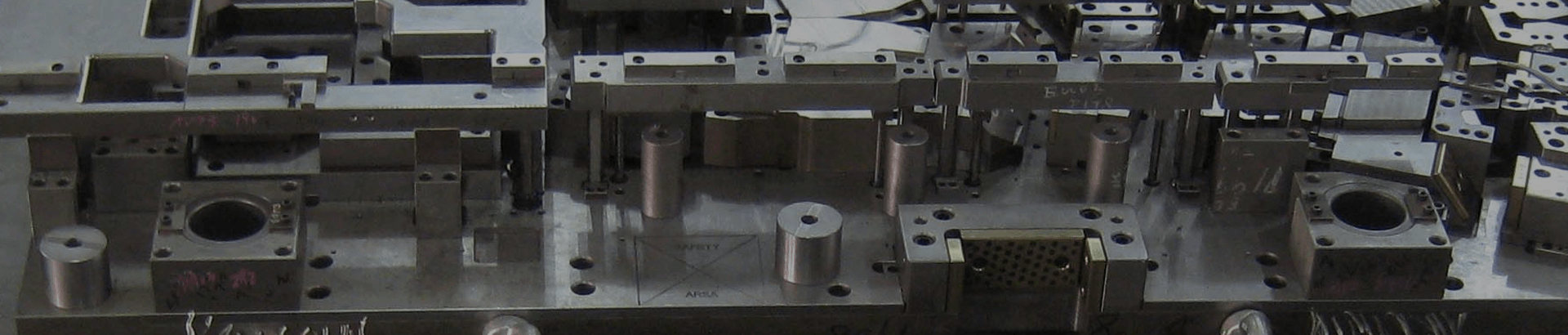

Kenmold is automotive plastic injection tooling manufacturer, we can design specifically for each vehicle model. Kenmold would consider the function of the parts and help customers to perfect the design of tools.

+1 270-282-2096

+1 270-282-2096