Choosing the right injection mold supplier is crucial for the success of your project, especially in industries like automotive where precision and reliability are paramount. Whether you're in the market for automotive injection molding, plastic injection molding, or sourcing automotive parts, finding a professional injection molding company can make a significant difference. Here’s a comprehensive guide on how to select the best injection mold supplier for your needs.

Before diving into the search, it's essential to have a clear understanding of your project requirements. Consider the following:

Material Specifications: What type of plastic material do you need? Different materials have varying properties and applications.

Production Volume: Are you looking for a supplier that can handle small batches or large-scale production?

Complexity of Design: How intricate is your product design? Ensure the supplier has experience with similar complexities.

Quality Standards: What industry standards and certifications does your project need to meet?

Experience in your specific industry is invaluable. For automotive injection molding, a supplier with a proven track record in producing automotive parts is preferred. They will be familiar with industry standards, common challenges, and regulatory requirements.

3. Assess Technological Capabilities

Modern injection molding relies heavily on advanced technology. When evaluating potential suppliers, consider:

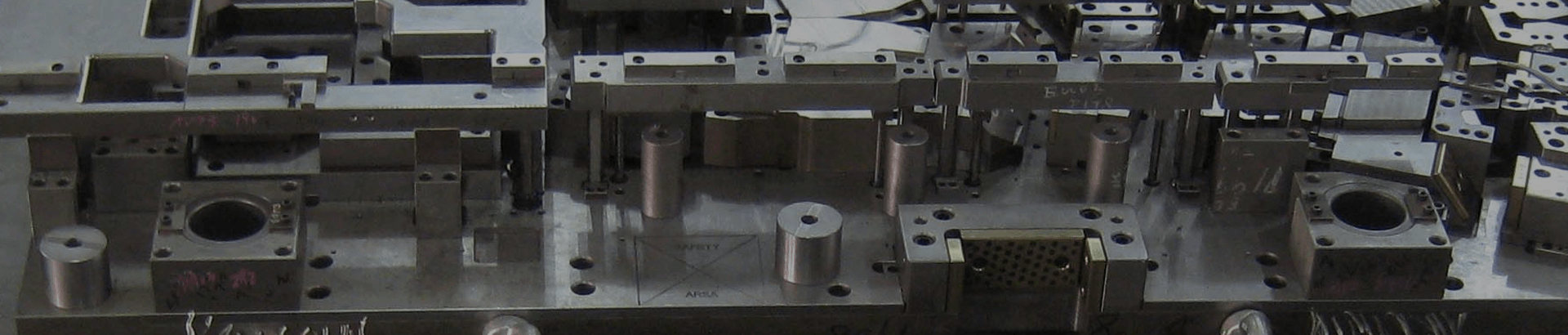

Machinery and Equipment: Ensure the supplier has state-of-the-art machinery capable of producing high-quality parts with precision.

Automation and Robotics: Advanced automation can improve efficiency and consistency.

CAD/CAM Software: High-quality design software is essential for accurate mold design and prototyping.

Quality control is a non-negotiable aspect of injection molding. A professional injection molding company should have robust quality control processes in place, including:

In-House Testing: Look for suppliers that perform rigorous in-house testing and inspections.

Certifications: ISO certifications (like ISO 9001) are a good indicator of a supplier’s commitment to quality.

Traceability: The ability to trace materials and processes can be critical for accountability and troubleshooting.

A supplier with strong design and engineering support can help optimize your product for manufacturability and cost-efficiency. Consider suppliers that offer:

Design for Manufacturability (DFM): Expertise in DFM can significantly reduce production costs and improve product performance.

Prototyping Services: Access to rapid prototyping can accelerate your product development cycle.

Engineering Expertise: Skilled engineers can assist with troubleshooting and optimizing the mold design.

A reputable supplier should be willing to share their portfolio and provide references. Reviewing past projects can give you insight into their capabilities and quality of work. Don't hesitate to contact their clients to ask about their experiences.

7. Assess Communication and Customer Service

Effective communication is vital for a successful partnership. Evaluate the supplier’s responsiveness, willingness to collaborate, and ability to provide clear and concise updates throughout the project.

8. Consider Logistics and Location

While the supplier's location may not be a deal-breaker, it’s worth considering logistics:

Proximity: A local supplier can reduce shipping costs and lead times.

Global Reach: If you’re planning for large-scale production, a supplier with a global presence might offer more flexibility and scalability.

Cost is always a critical factor. However, the lowest price doesn't always mean the best value. Consider the following:

Total Cost of Ownership: Factor in all costs, including tooling, production, shipping, and potential rework.

Value for Money: Assess what you're getting for the price. Sometimes, paying a bit more for higher quality and better service can save money in the long run.

If possible, visit the supplier’s facility. This visit can provide invaluable insights into their operations, cleanliness, organization, and the overall working environment.

Conclusion

Choosing the right injection mold supplier involves careful consideration of many factors. By understanding your needs, evaluating the supplier’s experience, technology, quality control, design support, and customer service, you can make an informed decision. Prioritize finding a partner who is not only capable of delivering high-quality plastic injection molding automotive parts but also committed to supporting your project from start to finish.

+1 270-282-2096

+1 270-282-2096