Choosing the right injection molding supplier is a critical decision that can profoundly impact the success of your manufacturing endeavors, especially in the realm of plastic injection molding. With a myriad of options available, selecting the ideal partner requires a thorough evaluation process. Here’s a comprehensive guide on how to navigate this selection process, incorporating essential keywords like Plastic injection molding, injection molding supplier, Injection tooling suppliers, and Kenmold.

Evaluate Industry Experience and Expertise

Begin by assessing the industry experience and expertise of potential injection molding suppliers. Look for companies with a proven track record in Plastic injection molding, particularly those well-versed in the nuances of the process. Kenmold, renowned for its expertise in injection molding, stands as an example of a reputable supplier. Prioritize suppliers with a history of successfully delivering projects similar to yours, demonstrating their ability to meet your specific requirements.

Review Production Capabilities and Technology

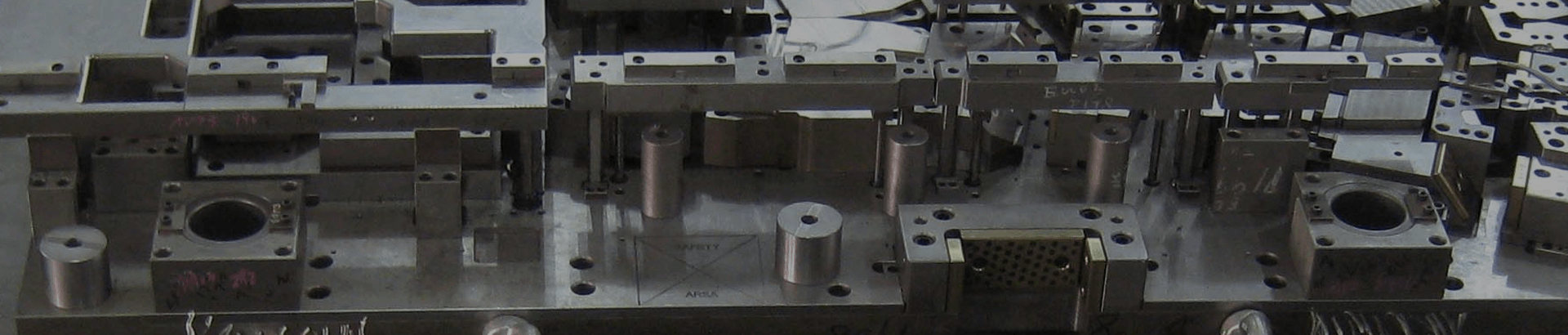

Next, delve into the production capabilities and technology employed by each supplier. Evaluate the machinery, equipment, and manufacturing processes they utilize, ensuring they align with your project needs. Injection tooling suppliers like Kenmold often boast state-of-the-art facilities equipped to handle a diverse range of projects. Their advanced capabilities can streamline production, enhance efficiency, and elevate the quality of your molded components.

Consider Quality Assurance Measures

Quality assurance is paramount in injection molding to uphold product integrity and reliability. Prioritize suppliers with robust quality assurance measures in place, such as stringent inspection protocols and adherence to industry standards. Kenmold, renowned for its commitment to quality, exemplifies a supplier dedicated to ensuring the highest standards of excellence. Verify certifications and accreditations, such as ISO 9001, as indicators of a supplier's adherence to quality management systems.

Assess Customization and Design Support

Tailored solutions and comprehensive design support are invaluable attributes in an injection molding supplier. Seek partners capable of providing personalized assistance throughout the design and development process. Injection tooling suppliers like Kenmold excel in offering customization options and expert guidance to optimize mold design and enhance product performance. Collaborative partnerships facilitate innovation and enable the creation of bespoke solutions tailored to your unique specifications.

Balance Cost-effectiveness with Quality

While cost is a significant consideration, it should not overshadow the importance of quality and reliability. Strive to strike a balance between cost-effectiveness and product excellence when evaluating potential suppliers. Kenmold, known for delivering exceptional value without compromising on quality, exemplifies a supplier capable of meeting stringent cost requirements while maintaining high standards of craftsmanship. Factor in total cost of ownership, including tooling expenses, production costs, and long-term maintenance considerations.

Ensure Timely Delivery and Reliability

Timely delivery is essential to maintaining production schedules and meeting customer demands. Prioritize suppliers with a proven track record of reliability and on-time delivery. Kenmold's reputation for punctuality and adherence to deadlines underscores the importance of partnering with a dependable supplier. Clear communication and efficient project management practices contribute to seamless collaboration and ensure timely completion of projects.

Emphasize Customer Service and Support

Lastly, prioritize suppliers that prioritize customer service and offer ongoing support throughout the project lifecycle. Responsive communication, transparent collaboration, and proactive problem-solving are hallmarks of a reliable partner. Kenmold's dedication to customer satisfaction exemplifies the importance of fostering strong client relationships built on trust and mutual respect.

Conclusion

Selecting the right injection molding supplier involves careful consideration of various factors, including industry experience, production capabilities, quality assurance measures, customization options, cost-effectiveness, delivery reliability, and customer service. By conducting a thorough evaluation and prioritizing suppliers like Kenmold that embody excellence in Plastic injection molding, you can forge a successful partnership that drives innovation, efficiency, and success in your manufacturing endeavors.

+1 270-282-2096

+1 270-282-2096