Overmolding is a technique where a layer of material is molded over an existing component. This process is often used to add features such as grips, seals, or aesthetic elements to a base part. The primary advantage of overmolding is its ability to integrate multiple materials into a single piece, enhancing functionality and appearance without requiring additional assembly steps.

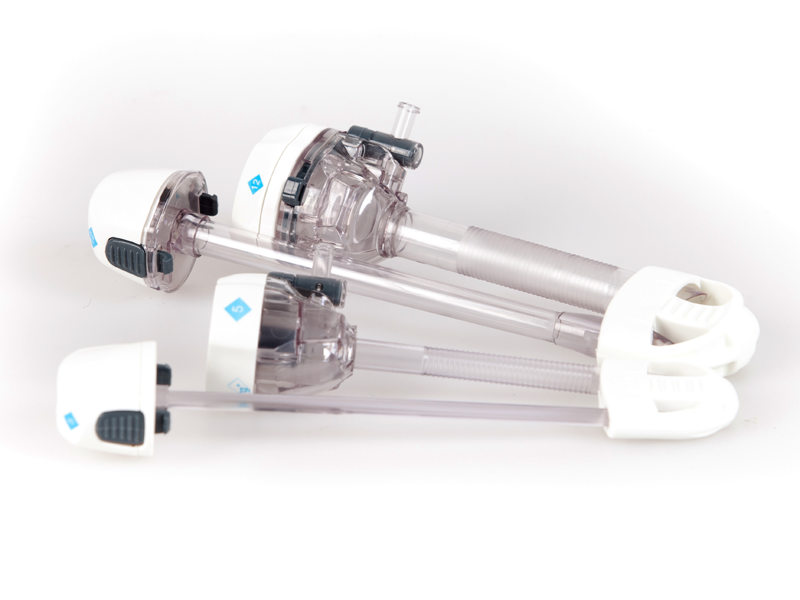

On the other hand, two-shot molding—sometimes referred to as two-shot injection molding—involves injecting two different materials into a single mold in sequence. This process allows for the creation of complex parts with varied material properties, such as different colors or hardness levels, within one finished product. The ultimate benefit of two-shot molding is its efficiency in producing multi-material parts with precise control over the material placement and bonding.

Both two-shot molding and overmolding offer unique advantages depending on the application. Overmolding is ideal for adding features to an existing base part, while two-shot molding excels in creating complex, multi-material components in one go. Understanding these differences can guide you to the most effective solution for your manufacturing needs.

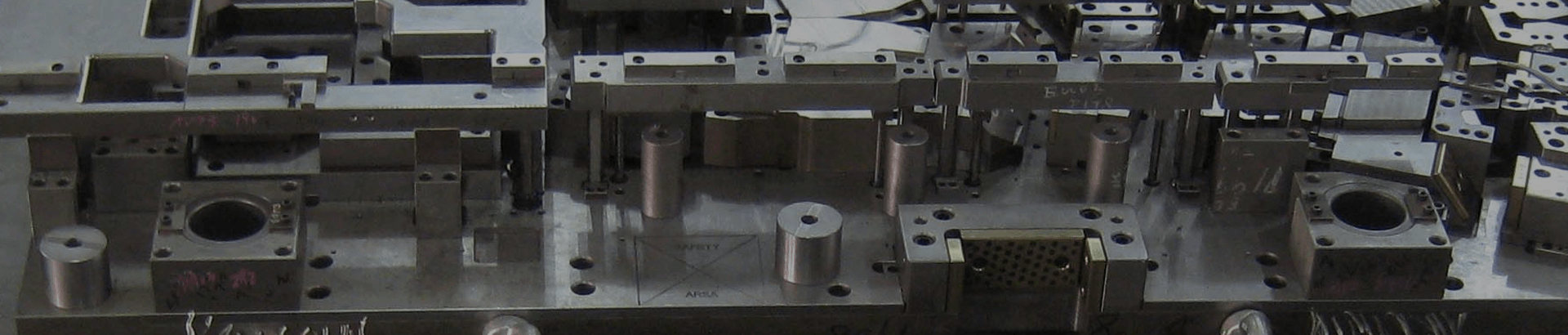

Kenmold is a professional custom plastic injection molding manufacturer. Kenmold Two Shot Injection Molding with resin ABS, silicone, PA6 and PC. Two shot injection molding Product post-process with print for logo and product specification. Sterilization process will be done before assembly and packaging. We offer a one-step solution for custom injection molding, die casting mold. More info at kenmold.com.

+1 270-282-2096

+1 270-282-2096