Plastic toys are an integral part of childhood, bringing joy and creativity to kids around the world. But have you ever wondered how these toys are made? The process of molding plastic toys is a fascinating journey that combines technology, precision, and creativity. In this blog post, we’ll explore the process of plastic toy molding and highlight the key roles played by injection tooling suppliers, custom plastic injection molding, and the entire manufacturing process.

1. Designing the Toy

The first step in the plastic toy molding process is designing the toy. Designers work closely with engineers to create detailed 3D models of the toy, ensuring that it will be both functional and aesthetically pleasing. This design phase also involves selecting the right type of plastic material that will provide the desired durability and safety for the toy.

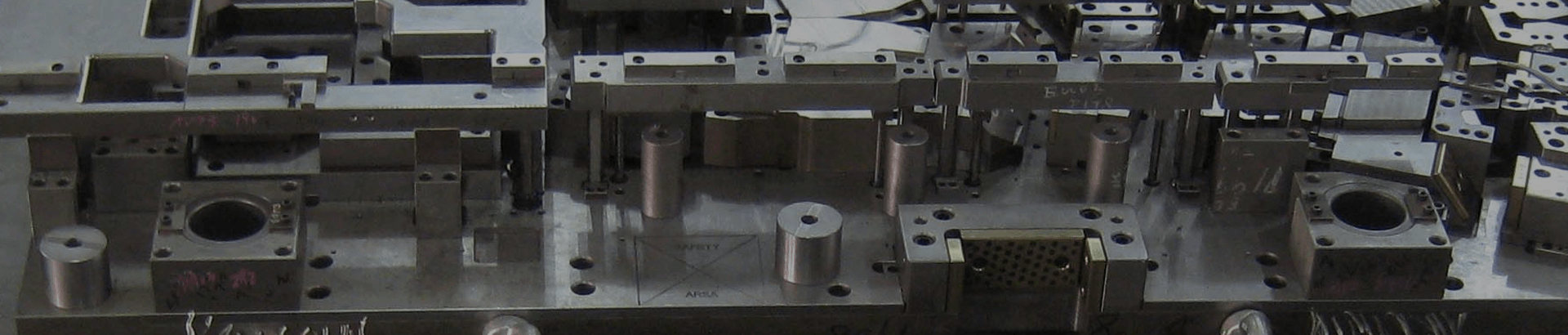

2. Creating the Mold

Once the design is finalized, the next step is to create the mold. This is where an injection tooling supplier comes into play. The mold, usually made of steel or aluminum, is crafted with precision to match the design of the toy. It consists of two halves: the cavity (which forms the exterior of the toy) and the core (which forms the interior). The accuracy of the mold is crucial, as it directly impacts the quality and detail of the final product.

3. Injection Molding Process

With the mold ready, the plastic toy molding process begins. This is where custom plastic injection molding techniques are applied. The chosen plastic material is heated until it becomes molten and is then injected into the mold under high pressure. The molten plastic fills the mold cavity, taking the shape of the toy. This process is quick, allowing for mass production of toys with consistent quality.

4. Cooling and Ejection

After the molten plastic has filled the mold, it needs time to cool and solidify. Cooling channels within the mold help expedite this process. Once the plastic has hardened, the mold opens, and the toy is ejected from the mold. This step may be repeated thousands of times in a production run, producing identical toys with high efficiency.

5. Trimming and Finishing

The molded toy often has excess plastic, known as flash, that needs to be trimmed away. Workers or automated machines trim the flash, ensuring that the toy has smooth edges and surfaces. Depending on the design, the toy may also undergo additional finishing processes such as painting, assembling, or adding decals to achieve the final look.

6. Quality Control and Packaging

Before the toys are packaged and shipped, they undergo a rigorous quality control process. This ensures that each toy meets safety standards and is free from defects. Once approved, the toys are packaged and prepared for distribution.

The Role of Injection Tooling Suppliers

Injection tooling suppliers play a pivotal role in the plastic toy molding industry. They provide the necessary molds and tooling equipment that ensure each toy is produced with precision and consistency. The quality of the mold directly impacts the quality of the final product, making the selection of a reliable injection tooling supplier essential for manufacturers.

Custom Plastic Injection Molding for Unique Designs

For toy manufacturers looking to create unique or specialized toys, custom plastic injection molding is the solution. This process allows for the customization of molds to create toys with specific features, shapes, or functions that stand out in the market. Customization is especially important in a competitive industry where innovation and creativity are key to success.

Conclusion

The process of molding plastic toys is a complex and fascinating journey that involves multiple steps and the expertise of various professionals. From the initial design to the final product, every stage is crucial in bringing a toy to life. Injection tooling suppliers and custom plastic injection molding techniques ensure that the toys we see on store shelves are of the highest quality, ready to spark joy in children everywhere.

+1 270-282-2096

+1 270-282-2096