2K injection molding, also known as two-shot molding or dual-shot molding, is an advanced manufacturing process used to produce complex and functional parts with multiple materials or colors. This innovative technique is widely employed in industries like automotive, consumer electronics, medical devices, and packaging due to its ability to combine materials seamlessly and enhance product design and performance.

What is the 2k injection molding process?

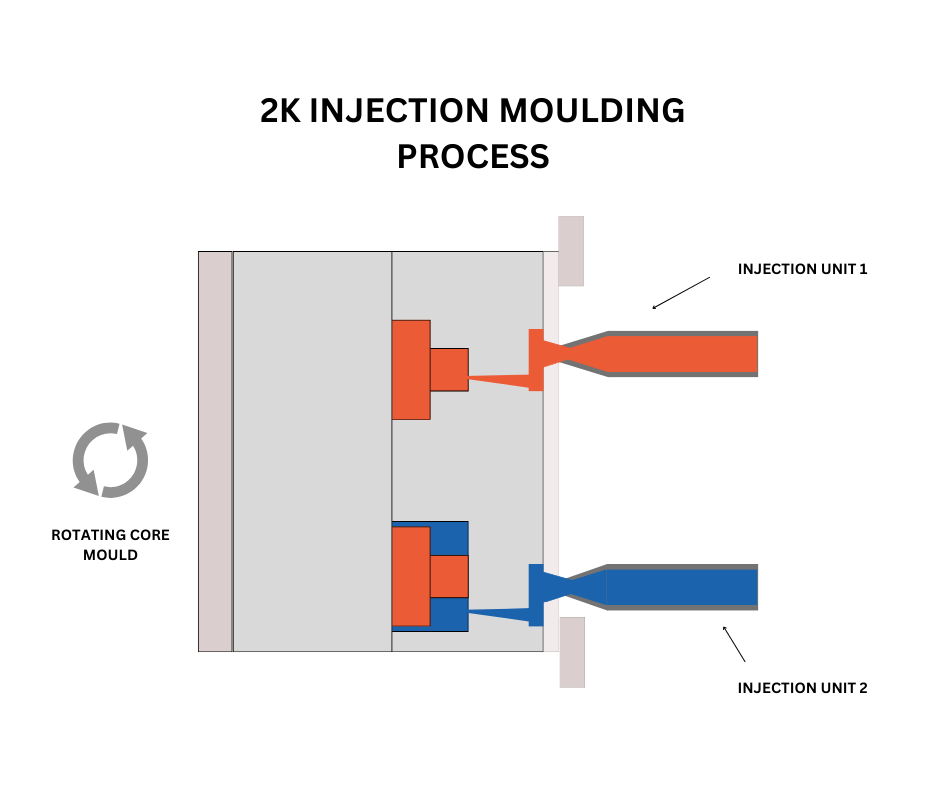

Both materials are simultaneously injected into the mold cavity during the 2K molding process. Typically, there are two types of materials: an elastic substance like TPE or TPV and a stiff material like polypropylene. Compared to conventional single-material injection molding, the combination of two materials enables more intricate designs and improved functioning.

Step 1: The first material, usually the base or substrate, is injected into the mold to form the core structure of the part. This material often serves as the foundation for the product.

Step 2: After the first shot has solidified, the mold either rotates or shifts to a second position. This allows the second material to be injected into the mold without disrupting the first shot.

Step 3: The second material is injected into the mold. This material can bond with the first shot or remain as a distinct layer, depending on the design and material compatibility.

Step 4: The combined product is cooled, solidified, and ejected from the mold as a single integrated part.

Applications of 2K Injection Molding

Automotive: Used for manufacturing interior components like dashboards, switches, and buttons with a combination of hard and soft materials.

Consumer Electronics: Produces durable and attractive parts for smartphones, wearables, and electronic casings.

Medical Devices: Creates ergonomic and functional medical tools, such as syringes and surgical grips.

Packaging: Makes innovative packaging solutions with sealing features or dual-material designs.

At kenmold, our team of experts in injection molding can provide turnkey solutions for your 2k injection molding projects, for a variety of applications in the medical and pharmaceutical, diagnostics, drug delivery and other applications. We are ISO 9001 and ISO 13485 accredited, with ISO Class 4 cleanrooms and more than 20 years of experience supplying precision molds and injection molding solutions to major life sciences companies all over the world.

+1 270-282-2096

+1 270-282-2096