High-Density Polyethylene (HDPE) is a versatile and widely used thermoplastic material, especially for injection molding applications. Known for its durability, chemical resistance, and high tensile strength, HDPE is commonly used in various industries to manufacture products like pipes, fittings, and containers. But when it comes to injection molding, what specific grade of HDPE is ideal for producing high-quality parts?

The Right Grade for Injection Molding

When selecting HDPE for injection molding, it’s important to choose the right grade to ensure optimal performance and longevity. Generally, HDPE grades for injection molding are classified based on their molecular weight and melt flow index (MFI). High-molecular-weight HDPE grades are commonly used for injection molding as they offer enhanced strength, impact resistance, and stiffness. These properties make them ideal for manufacturing HDPE pipes and injection pipe fittings, which require materials that can withstand high-pressure environments.

Why HDPE is Perfect for Injection Molding Applications

HDPE is a go-to material for injection molding because of its ease of processing and versatility. Its low cost, resistance to chemicals, and high strength-to-density ratio make it a popular choice in the production of components such as HDPE pipes and injection pipe fittings, used in plumbing, gas distribution, and industrial applications. Additionally, HDPE can be molded into complex shapes with high precision, making it a reliable material for various industries.

Injection Molding Supplier: The Role of Material Selection

Choosing the right material from an experienced injection molding supplier is crucial. High-quality HDPE, when combined with the right grade and manufacturing process, ensures that the molded parts meet the required specifications and provide excellent durability. Whether you're producing HDPE pipe fittings or custom parts, an experienced supplier can help you select the right HDPE grade for injection molding that will deliver both cost-effectiveness and quality.

Why Choose Kenmold for Your Injection Molding Needs?

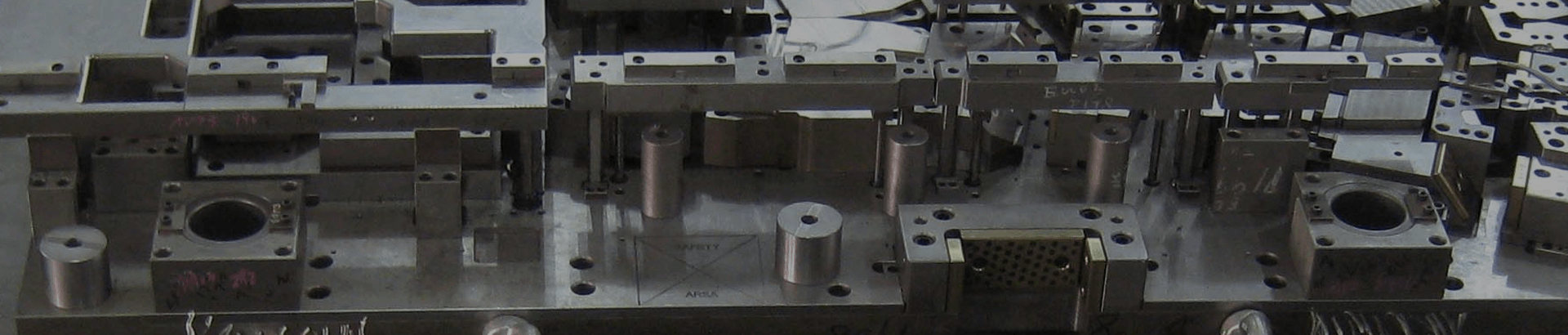

When it comes to high-precision injection molding, Kenmold stands out as a trusted supplier. With years of experience in manufacturing custom HDPE injection molded parts, Kenmold ensures that every product meets the highest quality standards. From HDPE pipes to intricate injection pipe fittings, their state-of-the-art molding technology and expert team deliver top-notch results every time.

Kenmold’s commitment to innovation and quality ensures that your injection molding projects run smoothly, with precision and efficiency. Contact Kenmold today to learn how their expertise can elevate your injection molding production process.

By choosing Kenmold, you're guaranteed a reliable partner for your HDPE injection molding needs, ensuring long-lasting, high-performance products for your business.

+1 270-282-2096

+1 270-282-2096