The automotive industry demands speed, precision, and efficiency at every stage of product development. From concept design to mass production, manufacturers need processes that can shorten lead times without compromising quality. Automotive injection molding has become one of the most important manufacturing methods to meet these goals. By working with an experienced injection mold maker or injection manufacturer, companies can efficiently transition from prototype to production.

Why Injection Molding Matters in Automotive Development

Injection molding is widely used in the automotive sector to produce both large and small components. Bumpers, dashboards, interior trims, and under-the-hood parts can all be manufactured using this method. The process allows for:

High-volume production with consistent quality

The ability to create complex geometries and fine details

Compatibility with lightweight and durable materials

Because of these advantages, injection molding supports faster product launches and ensures parts meet the rigorous standards required in the automotive industry.

From Prototype to Production: The Steps

- Design and Prototyping

Development begins with a 3D CAD design. Engineers can create prototypes using 3D printing or soft tooling, which helps test part performance, assembly fit, and functionality before investing in a full mold.

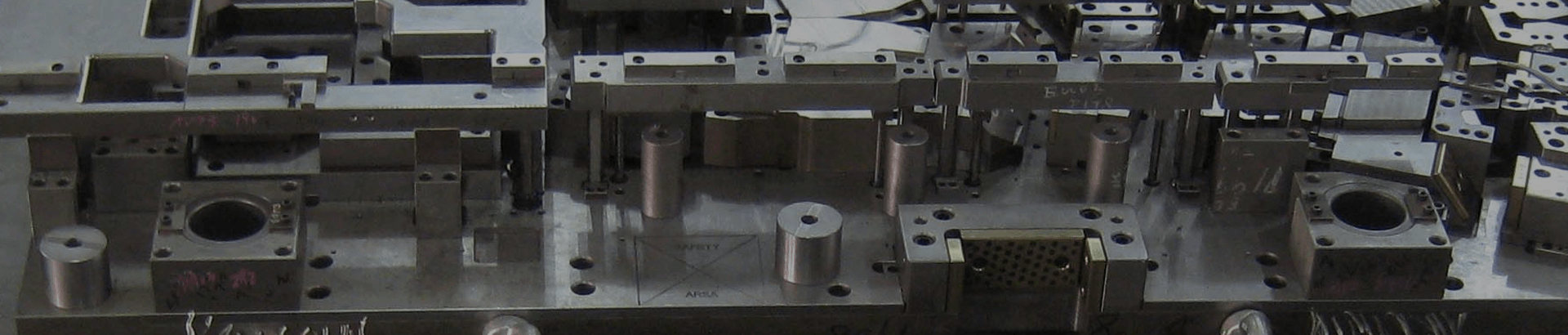

- Injection Mold Making

Once the design is validated, a precise mold is created. An experienced injection mold maker ensures that the tool is engineered for durability, efficiency, and accuracy. High-quality molds are critical, since they directly impact part consistency and production speed.

- Production and Scaling

Using the finished mold, an injection molding manufacturer can produce thousands—or even millions—of identical parts. Injection molding offers short cycle times, making it ideal for high-volume automotive manufacturing.

- Quality Control

At each stage, rigorous testing and inspection confirm that parts meet industry standards for safety, strength, and dimensional accuracy. This ensures reliability when components are integrated into vehicles.

Benefits of Automotive Injection Molding

Faster time to market: Designs can move quickly from prototype to production.

Cost efficiency: Low per-unit costs make injection molding ideal for large production runs.

Consistency: Each part produced matches exact specifications.

Flexibility: The process supports a wide range of materials and finishes.

Choosing the Right Partner

The choice of an injection mold maker or injection manufacturer plays a key role in the success of an automotive project. Important factors to consider include:

Proven experience in the automotive industry

Strong in-house tooling and engineering capabilities

Robust quality assurance processes

Ability to scale production efficiently

Conclusion

As vehicles evolve with advanced technology and lightweight materials, automotive injection molding continues to be a cornerstone of product development. The ability to move seamlessly from prototype to production makes it an essential process for manufacturers who need speed, precision, and reliability in a competitive market.

+1 270-282-2096

+1 270-282-2096