The simple answer is: yes. HDPE plastic can indeed be injection molded, making it a great choice for a wide range of products, including custom plastic injection molding parts. But how does this process work, and why is HDPE such a popular material choice for injection molding?

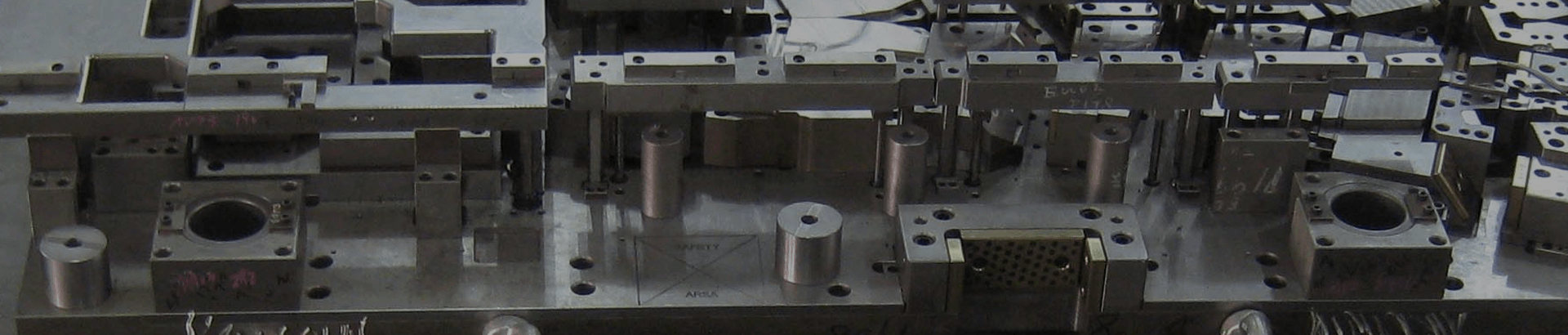

Injection molding is a highly efficient process used to create detailed, high-precision plastic parts. During this process, plastic material (like HDPE) is heated until it becomes molten and then injected into a mold to take the shape of the desired product. HDPE, with its low melt viscosity, flows smoothly into complex molds, making it perfect for creating plastic injection molded parts with intricate designs.

HDPE is particularly well-suited for injection molding because of its excellent processing properties, which allow it to be molded at high speeds with relatively low energy consumption. Additionally, HDPE can be reinforced with additives like colorants or UV stabilizers, making it adaptable for various uses in industries such as plumbing, packaging, and automotive.

One of the major advantages of using HDPE for custom plastic injection molding is its ability to produce strong, lightweight, and durable parts. HDPE is resistant to impact, moisture, and chemicals, making it ideal for products that need to withstand harsh environments. Furthermore, HDPE parts have a smooth surface finish, which reduces the need for additional finishing processes, saving time and money in production.

HDPE pipes, for example, are commonly manufactured using injection molding due to their high strength-to-weight ratio, which makes them both cost-effective and reliable for transporting liquids and gases. Whether it’s for plumbing or industrial applications, HDPE injection molded products offer a high level of performance and versatility.

When it comes to custom plastic injection molding, Kenmold is a trusted name in the industry. Specializing in precision injection molding, Kenmold offers high-quality plastic injection molded parts with fast turnaround times. Their team of experienced engineers works closely with clients to design and produce molds that meet specific needs, ensuring top-quality results every time.

Kenmold's commitment to excellence extends beyond just manufacturing. They offer comprehensive customer support, including prototyping, mold design, and post-production services. Whether you need HDPE parts for HDPE pipes or any other custom plastic injection molding projects, Kenmold's dedicated team is ready to bring your ideas to life with precision and efficiency.

+1 270-282-2096

+1 270-282-2096