1. Automotive: Used for manufacturing interior components (dashboards, door panels, seating), exterior parts (bumpers, lights), and engine components (valve covers, intake manifolds).

2. Medical: Produces disposable items such as syringes, vials, IV components, and medical device housings due to the process's ability to meet strict cleanliness and precision requirements.

3. Packaging: Injection molding is used for producing caps, closures, containers, and other packaging components due to its ability to create precise shapes and sizes with high production rates.

4. Consumer Goods: Various consumer products like kitchenware, electronic enclosures, toys, and household items benefit from injection molding's capability to achieve complex designs cost-effectively.

5. Electronics: Enclosures, connectors, and housings for electronic devices are often made through injection molding due to its ability to integrate features like snap fits and intricate geometries.

6. Industrial Equipment: Parts for machinery, tools, and equipment benefit from the durability, precision, and scalability offered by injection molding.

7. Aerospace: Components requiring lightweight materials, complex geometries, and high-performance polymers are often manufactured using injection molding.

8. Construction: Injection molding is used for producing parts like pipes, fittings, and other building materials due to its ability to create durable and weather-resistant products.

9. Toys: Many plastic toys are manufactured using injection molding because of its ability to produce large quantities of identical items with intricate details.

10. Furniture: Parts for furniture such as chair shells, table legs, and decorative elements can be efficiently produced using injection molding.

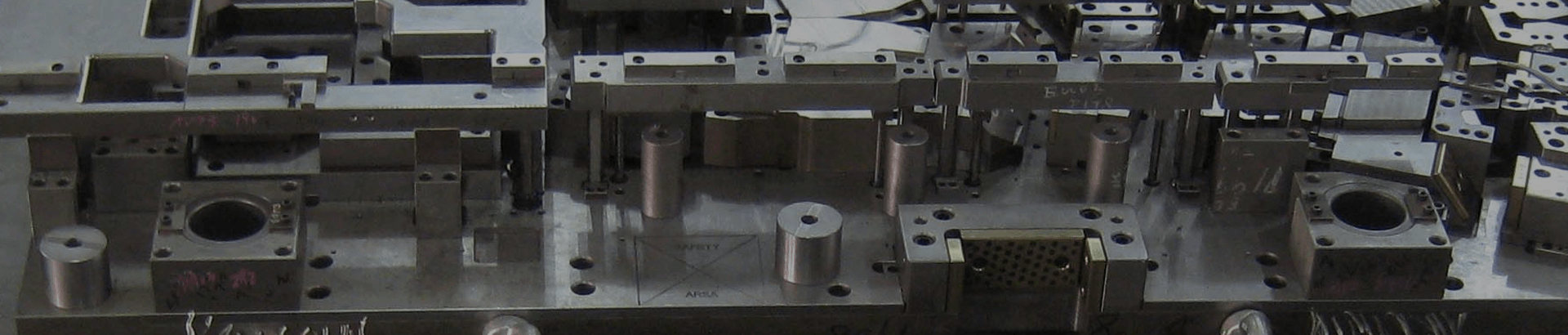

Kenmold is an ISO9001:2008 and ISO13485 certified high-performance, cost-effective custom mold manufacturer, including plastic injection molding, die casting and rubber molds for automotive (interior and exterior), home appliances, electronics, packaging, medical, etc. Kenmold provides one-stop OEM medical injection molding, Automotive mold, Electronics and Home Appliance injection molding solutions. More info at kenmold.com, Welcome to inquire!

+1 270-282-2096

+1 270-282-2096