Introduction

In mid 2005, The CEO of Kenmold. Mr. Zhong Jianwu sat in his office reflecting upon the events of the past few months. His company had recently turned a corner in the business of contract manufacturing and product development. Profits were up, business was booming, and the world market had shifted such that his firm was well positioned to grow. However, Mr. Zhong Jianwu couldn't help but feel like there were more changes to be made to ensure future success. A project to make a new "pool bike" for aquatic exercise had just entered litigation, and the related failures were constantly on his mind as a harbinger of future problems if changes weren't made.

Pool bike lessons for the future of contract R & D

Kenmold grew quickly from a purely contract manufacturing firm into a full-service engineering, design, development, and manufacturing company. The majority of its clients were from outside of China. In the beginning, most business transactions revolved around meeting customer requirements and specifications.More recently, in order to separate themselves from the competition, Kenmold had begun to take on projects with few formal customer specifications and do the engineering and development work for the customer. They serviced the automotive,home appliance, aluminum die casting, industrial, and finished goods markets now and were faced with increased competition from lower cost nations in South East Asia.

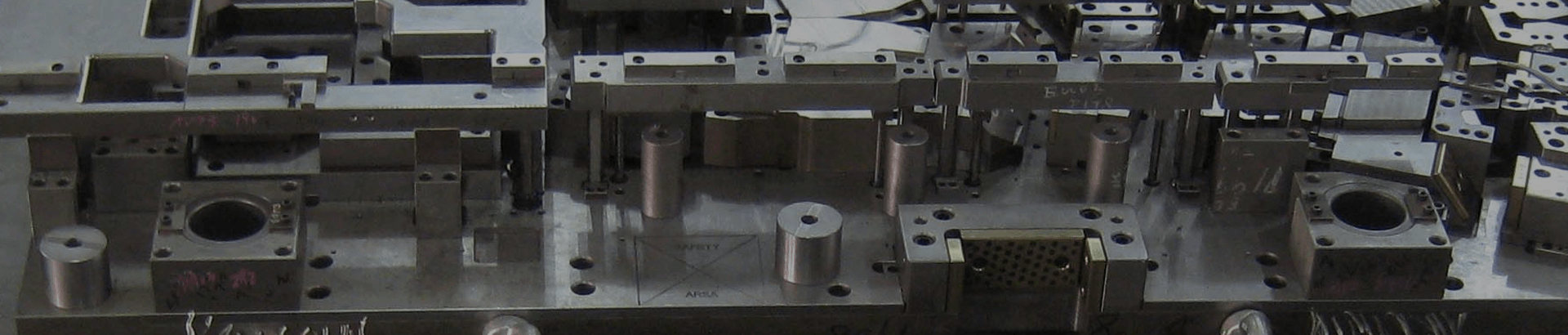

Kenmold was known for their Project Development System, which provided total solutions to their customers. The system covered the concept discussion, mold design and tooling manufacturing,part manufac-turing,assembly, post processing (painting/packaging),and ship-ment. The making of assembled finished products was complicated. It was a process that not only includes the product's style and function but also the post treatment such as assembling, painting, plating, packaging etc. Customers trusted Kenmold's Project Development System to make new products that would hit the market quickly within a short cycle of development. The key competitive advantage for Kenmold in the Contract R&D market was its ability to quickly take an idea and make it into a final product.

Pool Bike Project

In November of 2001, Kenmold was approached by two investors from Monaco. Kenmold was asked to quote on design, development, and manufacture for a line of exercise pool bikes. The investors had been selling pool bike products for over 15 years and were licensed to sell in the EU and US markets. Kenmold submitted a quote as asked but heard nothing until October 2003. The investors had chosen a competitor instead, and by 2003 were unhappy with the work done. The relationship between the investors and the competitor had ended badly and gone to court. A new development and manufacturing firm was needed to complete the project. Kenmold re-quoted the project and received the order.

Then things turned nasty. The increase in tooling and part costs was communicated with the customer in April of 2005. The customer to the customer in April of 2005. The customer refused to pay the increase in tooling and became angry with Kenmold, but begrudgingly paid the second installment of US$50,000 as per the original contact. The customer arrived in May with a check for US$50,000. Jianwu's partner did not trust the check to clear. The bank informed Kenmold that it would take more than 90 days to clear such a check. By August of 2005, the customers and Kenmold were in a legal battle. Kenmold was paid only US$110,000 dollars and was still owed more than US$70,000 in tooling and development costs. The customers were using to get the molds and were shopping around for other manufacturers in South East Asia in the mean time. Kenmold, of course, would not release the molds until such time as payment was received in full, and they had recouped the costs invested in the project.

Jianwu thought that the Pool Bike project was a sign that Kenmold needed to change its bidding and contract process. The increasing number of international firms contracting R&D services in China meant that Kenmold would likely increase their market and grow with the industry. However, if they wanted to become the industry best Without understanding the technologies and the processes of developing the new product -- in this case, the pool-bike -- the client couldn't analyze the costs Kenmold had to incur properly. That caused several misunderstandings: the client believed that small changes in the mold and part would result in equivalently small changes in the costs. But in reality, these changes led to significant design changes in the mold used to build key pieces of the pool bike, greatly increasing the price.

Analysis of the Problems

The interview with the chief executive of Kenmold unveiled some problems:

manufacturer didn't receive the full sum of money and the client didn't receive the mold. Further distrust was caused when the client tried to pay by bank check, instead of transferring cash immediately.

In outsourcing, as it was said above, choosing the right company is a key success factor. But on the international market it is difficult to understand which company is worth your interest. First of all, it is difficult to get detailed information about many companies. As an outsider, in both the industry and country, you are unaware of the best sources of information. The best way to solve this problem could be an interpreter, someone who knows the industry and country which you are trying to evaluate. The same could go for the supplier company. It's difficult to find information about the financial status of a prospective customer, but it is necessary to make the decision about whether to participate in a business relationship or not

|

Rational |

Current project planning

Physical Distance Communication & Culture |

Costing Forecasting |

| Political |

Offloading Physical Distance |

Client offloading the entire cost burden of a project Easier for client to distance himself from the outsource firm |

|

Knowledge Management |

Exploitation vs Exploration |

Think the "Kenmold" way is the company able to proactively respond to market trends and changes? Can Kenmold learn from each customer and build a portfolio of market knowledge that can be applied across customers? Is the client exploring new product ideas with Kenmold, or are they exploiting Kenmold's technical knowledge without availing themselves of exploration opportunities? |

There is a great difference in the way of conducting business. Asian business culture supposes concessions. They are oriented on long-term relationship, which is why while developing the prototype Kenmold executives believed that their partners will cover all the expenses they incurred for product enhancement Kenmold thought that the client could easily recoup those costs in lowered per-unit costs down the road. We believe western businessmen prefer to know the total outlay from the beginning. For them it is difficult to accept that the price can significantly change. In this case, this resulted in a 50% increase in cost that the client would not pay. The end of the story is dramatic: the "go ahead" from the investors to begin R & D in November of 2003.

Kenmold completed the R&D CAD models of the new components for a prototype pool bike in December, but halted work as the customer payment was not received. Also, molds that were at the competitor's facility were needed to manufacture parts, but were not received due to legal issues between the former partners. This meant that Kenmold would have to design and build new tooling for component manufacture that wasn't in the original contract. An addendum to the original contract was created and prices were adjusted accordingly. The whole process was on hold for a year before the customers decided to retool with Kenmold. Kenmold began work on the new molds in January of 2005

The customers visited Kenmold in March of 2005 to see the prototype bike, review design changes, and inform Kenmold of the need for samples for a show in May. Kenmold had to rush the manufacture of the two main body molds in order to meet the show deadline, but the increased tooling cost of US$60,000 due to technological upgrades was not formally agreed to by all parties due to lack of time. Kenmold also did not get final confirmation on design changes by the customer which were needed to finalize designs and lock in material costs. It was a hectic time for everyone on the project. The customer needed the samples for the US show and time was short. they had to find a way to prevent the issues of the Pool Bike Project from repeating themselves.

Looking at this case, we can see that the client was primarily interested in saving money; immediate cost savings were the main impetus for the relationship with Kenmold. However, this approach led to some problems which resulted in lost time and money. As referenced in the case, the client lost two years and significant money with another Chinese factory in Qingdao.

Thus, if you decide to use outsourcing as a method of time and cost savings in a new product development you should understand the industry you move into very well. Choosing the right company is very essential in outsourcing.

·the lack of investor`s knowledge of the manufacturing sector

·different cultural backgrounds

·different business cultures the lack of information on the clients and suppliers low levels of communication

One of the main reasons why this project might be deemed a failure is that there were not only cultural differences that contributed to the problem, but that an inefficient communication between these two companies made it impossible to have immediate feedback between Kenmold and the client. If Kenmold managers needed information from the customer, there were times when they couldn't get in touch with them not due to any fault of Kenmold's, but due to a refusal of the client to reply in time.

Discussion Points and Relevant Literature

Implications: what does this imply about the contract and R&D market in outsource/offshore countries? What areas should we and future contributions to the literature discuss?

The Table Below Discusses Implied Future Areas of Research

|

·Research focused on global NPD knowledge sharing networks can they be made effectively? |

+1 270-792-5768

+1 270-792-5768 +1 270-282-2096

+1 270-282-2096